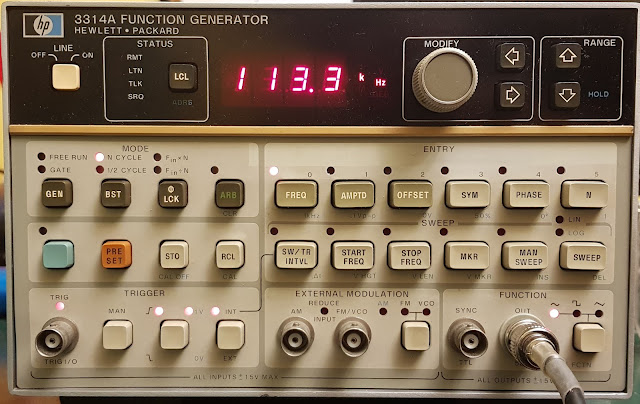

Some time ago I scored a nice looking HP 3314A function generator of eBay. It was advertised as not powering up, so there was a chance that there is some simple problem. I took a chance and was able to get it for cheap.

When it arrived, I took a closer look. I immediately noticed something rattling inside, and this is what I saw after I had opened it up.

One of the EPROMs was loose and bouncing around inside the case. I first though that it may be that simple, but a closer look provided a much gloomier forecast. The EPROMs were infact in a small adapter boards, so someone has been here before. The adapter boards by themselves are not a problem, the Mostek ROMs in these units are known to fail and can quite easily be replaced by 2764 EPROMs, using an adapter to fix the pinout differences.

However, the soldering job on these adapters were horrible. There were large blobs of solder everywhere, sockets being melted, bodge wires going over and under sockets, etc. So I was not too optimistic, when I reseated the EPROM. Especially that I noticed that two EPROMs had some of their pins crushed when they were apparently misaligned during insertion. See pin 19 of U208 in the above picture. Someone was very careless in the past. I fixed those, fortunately without breaking the bent pins.

Flipping the power switch, the fan starts, but no sign of life. Not even the ROM checksum test.

OK, lets dig deeper. First the trivial stuff. Power rails were good, all within spec with voltage and ripple. Next, check the CPU activity. Ooops! Out of the two clock signals, only one is there, that can't be good.

Let's go and follow the signal path for the clock. The two-phase clock is derived from the master crystal oscillator and I very quickly discovered that the problem is at a 74S74 IC. Interestingly enough, this IC is in a socket, so looks like someone replaced it at some point of time in the past. Hmmm. Anyway, because of the socket, I was quickly able to replace it, without any effect.

It was time to examine the board more carefully. I removed it from the clever fold out metal sheet, and this is what I saw.

The previous owner had butchered the PCB for the U201, the 74s74. (I'm not sure what he was using, a flamethrower and some blacksmith tools maybe.) Anyway a trace was broken at one of the pins and replaced with a jumper wire. Which became pinched under one of the screws holding down the board and got grounded. No wonder the clock was a flat-liner. I guess this worked for some time while the insulation got chewed up, or the screw was finally tightened, so this is why the previous repairer did not notice it.

I redid the soldering and patched the trace, so got rid of the long wire. Immediately I had nice clock, but still no sign of life.

Next step is Signature Analysis (SA). Some like it, some don't, but HP was very keen on having this debug function in their CPU driven instruments. In my experience it can be a very useful and easy to use tool for some of the troubleshooting steps. I hooked up my Sony-Tektronix 308 Data Analyzer to go trough the SA tests. I still had a feeling that the ROMs would be the problems, but let's exclude everything else first.

The first test is the freerun test, when the CPU is fed a harmless instruction at every memory read to just sweep trough all the memory addresses. So we are basically supposed to see A15-A0 count up to cover the whole 64k memory range. With the SA this will also test most of the memory decoder functions.

The first attempt wasn't successful. The signatures on the CPU pins checked out fine, but two of the address lines after the 74LS373 latches were bad. I looked at then with a scope and looked like the two lines were shorted. Obviously the prime suspects were the 373s. Even more so, as there were huge blobs of solder on some of the pins on the component side. Looks like that someone wanted to replace them after the EPROM adapter cards were soldered in and they prevented from lifting the 373 out of the PCB and also inserting the new one. So he cut the offending pins flush with the bottom of the IC and then soldered them in from above. Which of course resulted in a short. Then probably at this time he gave up, and put the unit on eBay, where I got it.

I fixed the short, and then the freerun SA tests finally completed successfully. But still no sign of operation. Next came the ROM SA tests, which basically do a checksum like test on the EPROMs.

3 out of 6 ROMs were good, the rest did not give a stable reading. But by wiggling the ROMS, sometimes I got a good result. Obviously the excellent soldering skills of the previous owner struck again.

At this point I decided to remove all the ROMs, check the EPROM contents, check the adapter cards and check the PCB under the ROMs, as I felt that if the previous owner did such a massacre with a 14 pin IC, then a 24 pin would not be any better. And boy, I was right.

Stay tuned for the next part.